|

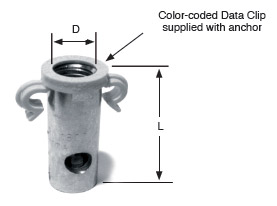

THREADED LIFTING SYSTEM

|

| |

| Uses innovative engineering to provide superior performance for edge lifting and tilting thin precast panels, with minimal or no patching. Supplied with color coded reinforcement clip for easy identification. Shear loading requires the use of one shear bar and one shear bow per anchor. Upper section of anchor is plated. |

| |

WAVED TAIL ANCHORS

Extended waved tail provides

exceptional tensile capacity in thin panels.

Can also be used in shear with

addition of a shear bow. |

|

|

| WTA005 |

Orange |

0.5 |

0.25 |

Rd12 |

137 |

152 |

57 |

76 |

| WTA008 |

White |

0.8 |

0.4 |

Rd14 |

168 |

203 |

64 |

83 |

| WTA012 |

Red |

1.2 |

0.6 |

Rd16 |

197 |

203 |

70 |

95 |

| WTA016 |

Pink |

1.6 |

0.8 |

Rd18 |

235 |

254 |

83 |

102 |

| WTA020 |

Light Green |

2 |

1 |

Rd20 |

257 |

279 |

89 |

114 |

| WTA025 |

Dark Grey |

2.5 |

1.25 |

Rd24 |

349 |

305 |

102 |

127 |

| WTA040 |

Emerald Green |

4 |

2 |

Rd30 |

451 |

355 |

121 |

152 |

| WTA063 |

Light Blue |

6.3 |

3.15 |

Rd36 |

568 |

406 |

159 |

203 |

| WTA080 |

Light Grey |

8 |

4 |

Rd42 |

619 |

508 |

178 |

241 |

| WTA125 |

Yellow |

12.5 |

6.25 |

Rd52 |

873 |

610 |

203 |

279 |

|

|

| |

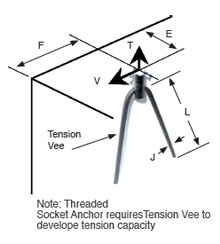

THREADED SOCKET ANCHORS

Can be used for a wide range of applications in precast construction such as lifting anchors for beams and grinders, wall and floor slabs, etc. To develop the load rating, a bent reinforcement bar must be inserted through the cross hole. Stocked in plated finish. |

|

|

Minimum panel

thickness = 2 x E. (as shown on tension Vees chart below)

If two or more anchors are used, minimum spacing = 2 x F. (as shown on tension Vees chart below)

Allowable Shear Capacity is valid for loads in any direction, parallel to the face of the concrete with shear bows.

Additional shear capacity can be achieved by reinforcing Threaded Socket Anchors in the ways shown on the following page. |

|

| TSA005 |

Orange |

0.5 |

Rd12x1.75 |

40 |

64 |

152 |

| TSA008 |

White |

0.8 |

Rd14x2.0 |

48 |

70 |

203 |

| TSA012 |

Red |

1.2 |

Rd16x2.0 |

54 |

80 |

203 |

| TSA016 |

Pink |

1.6 |

Rd18x2.5 |

65 |

95 |

254 |

| TSA020 |

Light Green |

2 |

Rd20x2.5 |

70 |

114 |

279 |

| TSA025 |

Dark Gray |

2.5 |

Rd24x3.0 |

78 |

127 |

305 |

| TSA040 |

Emerald Green |

4 |

Rd30x3.5 |

103 |

140 |

355 |

| TSA063 |

Light Blue |

6.3 |

Rd36x4.0 |

124 |

222 |

406 |

| TSA080 |

Light Gray |

8 |

Rd42x4.5 |

146 |

241 |

508 |

| TSA125 |

Yellow |

12.5 |

Rd52x5.0 |

194 |

279 |

610 |

|

|

| |

|

| Use with Threaded Socket Anchor |

Wire or Bar Size J [ mm ] |

Length for 2,200 psi concrete K22 [ mm ] (L) |

Length for 3,600 psi concrete K36 [ mm ] (L) |

Bend Diameter [ mm ] |

| TSA 005 |

6 |

216 |

171 |

25 |

| TSA 008 |

8 |

254 |

203 |

32 |

| TSA 012 |

10 |

305 |

241 |

38 |

| TSA 016 |

10 |

419 |

318 |

38 |

| TSA 020 |

12 |

432 |

343 |

50 |

| TSA 025 |

14 |

470 |

355 |

50 |

| TSA 040 |

16 |

648 |

495 |

64 |

| TSA 063 |

20 |

813 |

629 |

140 |

| TSA 080 |

25 |

838 |

648 |

178 |

| TSA 125 |

28 |

1168 |

902 |

203 |

|

|

| |

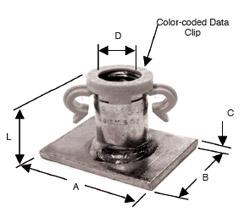

FLAT STEEL ANCHORS

Ideal for backstripping or face lifting thin precast panels. Supplied with color coded reinforcement clip for easy identification. Tension loads require the use of two Tension Bars per anchor. Shear loads require the use of two Tension Bars and one Shear Vee per anchor. Stocked in plated finish. |

|

| FSA005 |

0.5 |

Rd12x1.75 |

15 |

30 |

35 |

25 |

3 |

| FSA008 |

0.8 |

Rd14x2.0 |

18 |

33 |

35 |

35 |

3 |

| FSA012 |

1.2 |

Rd16x2.0 |

21 |

35 |

50 |

35 |

3 |

| FSA016 |

1.6 |

Rd18x2.5 |

24 |

44 |

60 |

44 |

5 |

| FSA020 |

2 |

Rd20x2.5 |

27 |

48 |

60 |

60 |

5 |

| FSA025 |

2.5 |

Rd24x3.0 |

31 |

54 |

79 |

60 |

5 |

| FSA040 |

4 |

Rd30x3.5 |

40 |

73 |

98 |

79 |

6 |

| FSA063 |

6.3 |

Rd36x4.0 |

47 |

97 |

130 |

98 |

6 |

| FSA080 |

8 |

Rd42x4.5 |

54 |

98 |

130 |

130 |

8 |

| FSA125 |

12.5 |

Rd52x5.0 |

67 |

117 |

149 |

130 |

8 |

|

|

| |

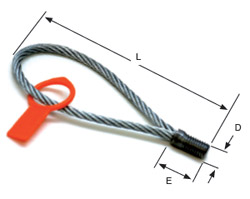

LIFTING LOOPS

Most economical lifting units for this system. Manufactured from flexible wire rope and tagged with a color code to match the capacity of the anchors. For tension only - limited to 30 degrees from vertical. Galvanized cable loop with mill finished threaded stud. |

|

| TLL005 |

Orange |

0.5 |

Rd12x1.75 |

15 |

20 |

156 |

| TLL008 |

White |

0.8 |

Rd14x2.0 |

18 |

22 |

156 |

| TLL012 |

Red |

1.2 |

Rd16x2.0 |

21 |

25 |

156 |

| TLL016 |

Pink |

1.6 |

Rd18x2.5 |

24 |

29 |

191 |

| TLL020 |

Light Green |

2 |

Rd20x2.5 |

27 |

32 |

216 |

| TLL025 |

Dark Grey |

2.5 |

Rd24x3.0 |

31 |

40 |

254 |

| TLL040 |

Emerald Green |

4 |

Rd30x3.5 |

40 |

55 |

305 |

| TLL063 |

Light Blue |

6.3 |

Rd36x4.0 |

47 |

67 |

339 |

| TLL080 |

Light Grey |

8 |

Rd42x4.5 |

54 |

79 |

432 |

| TLL125 |

Yellow |

12.5 |

Rd52x5.0 |

67 |

95 |

483 |

|

|

| |

| |

LIFTING LOOP WITH

PRESSURE PLATES

Most versatile lifting units for Waved Tail and Flat Steel Plate Anchors. Tagged with a color code to match the capacity of the anchors. Retain the flexibility of the regular Lifting Loops w/o the need for Distribution Basins when used in extreme shear conditions. Plated.

|

|

| TLP005 |

Orange |

0.5 |

Rd12 |

| TLP008 |

White |

0.8 |

Rd14 |

| TLP012 |

Red |

1.2 |

Rd16 |

| TLP016 |

Pink |

1.6 |

Rd18 |

| TLP020 |

Light Green |

2 |

Rd20 |

| TLP025 |

Dark Grey |

2.5 |

Rd24 |

| TLP040 |

Emerald Green |

4 |

Rd30 |

| TLP063 |

Light Blue |

6.3 |

Rd36 |

| TLP080 |

Light Grey |

8 |

Rd42 |

| TLP125 |

Yellow |

12.5 |

Rd52 |

|

|

| |

PLASTIC CAP

Used after casting to plug the

threaded opening in the anchors.

Grey plastic.

|

| TCS005 |

0.5 |

Rd12 |

20 |

| TCS008 |

0.8 |

Rd14 |

22 |

| TCS012 |

1.2 |

Rd16 |

25 |

| TCS012 |

1.6 |

Rd18 |

29 |

| TCS020 |

2 |

Rd20 |

32 |

| TCS025 |

2.5 |

Rd24 |

35 |

| TCS040 |

4 |

Rd30 |

44 |

| TCS063 |

6.3 |

Rd36 |

52 |

| TCS080 |

8 |

Rd42 |

60 |

| TCS125 |

12.5 |

Rd52 |

73 |

|

|

| |

|

| |